DB rolling stock maintenance, Dessau plant

Design ceiling FLUID-O in a 1500 x 1500 mm module with customer-specific organic shape

1 mm of electrolytically galvanised steel; powder-coated in RAL 9010; connected ex-factory with a metal acoustic ceiling

Metal acoustic ceiling as a beam ceiling

1 mm of electrolytically galvanised steel; powder-coated in RAL 7012; perforated in RD-L30 and lined with acoustic fleece [262 m²]

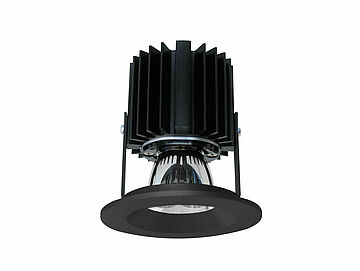

Downlight PUNTEO-J60 for FLUID

Light distribution: 2 x 35°; light colour: 4000 K; CRI >90 [32 pieces]

The Dessau plant, where rolling stock for German railway operator DB gets maintained, dates from 1929. The core competence of this plant involves the maintenance and overhaul of electric locomotives. It has one of the most modern locomotive testing centres in Europe and it has modernised the 'Casino' building (the company refectory) for its approximately 1,500 employees.

One aspect of the architectural firm’s vision was to create a special atmosphere as part of the roof renovation of the former refectory using a metal acoustic ceiling with organically shaped elements. We successfully implemented this very aesthetic concept with our FLUID-O design ceiling. To avoid the straight elements from detracting in any way from the visual impact of the rounded plates, this ceiling is designed with the FLUID elements rotated through 10°, but based on a linear arrangement within that interior space, framed with a plasterboard frieze.

To ensure that the 50 mm joint between the individual ceiling elements is identical throughout and that installation is an easy process, FLUID-O was designed ex-factory with a 10 mm gap separating the ceiling plates and the basalt-grey, acoustically effective metal beam ceiling. These plates are dimensioned and designed to fit perfectly in their suspended position, and to ensure that they can be removed again. This facilitated on-site orientation.

The suspended ceiling with its seven different plate types and a partially concealed 15 mm suspension joint adopts the size and linear arrangement of the FLUID elements by rotating them horizontally through 10°. With trapezoid-shaped edge panels, a narrow installation seam around the circumference of the beam ceiling separates it from the plasterboard frieze.

One of the challenges was to produce a connection between the rotated ceiling plates and the wooden beam of the roof structure. A U-shaped beam was used as a load-bearing element which was able to span the large distances needed between suspended elements and which facilitated symmetrical attachment to the roof structure.

The connection between the metal ceiling and the load-bearing element is designed to allow every second row of plates on the supporting ceiling to be suspended in special hangers and the intervening rows to be placed on the suspended plates. This significantly reduced the work involved for installation and assures rapid access to the ceiling void without the need for tools.

This design ceiling is rounded off with stylishly integrated PUNTEO-J60 downlights that are slightly recessed. Each luminaire was modified to prevent any unwanted light reflections from occurring on the FLUID-O elements, preserving the visual appearance of the ceiling.